The Evolution of Business: **Rapid Prototyping and Manufacturing** as a Game Changer

In today's fast-paced industrial environment, the ability to adapt, innovate, and deliver quickly is paramount for business success. Rapid prototyping and manufacturing have become integral components, revolutionizing how industries operate, particularly within sectors like metal fabrication. This article delves into the significance, benefits, and future trends of rapid prototyping and manufacturing, showcasing how these strategies fuel business growth and innovation.

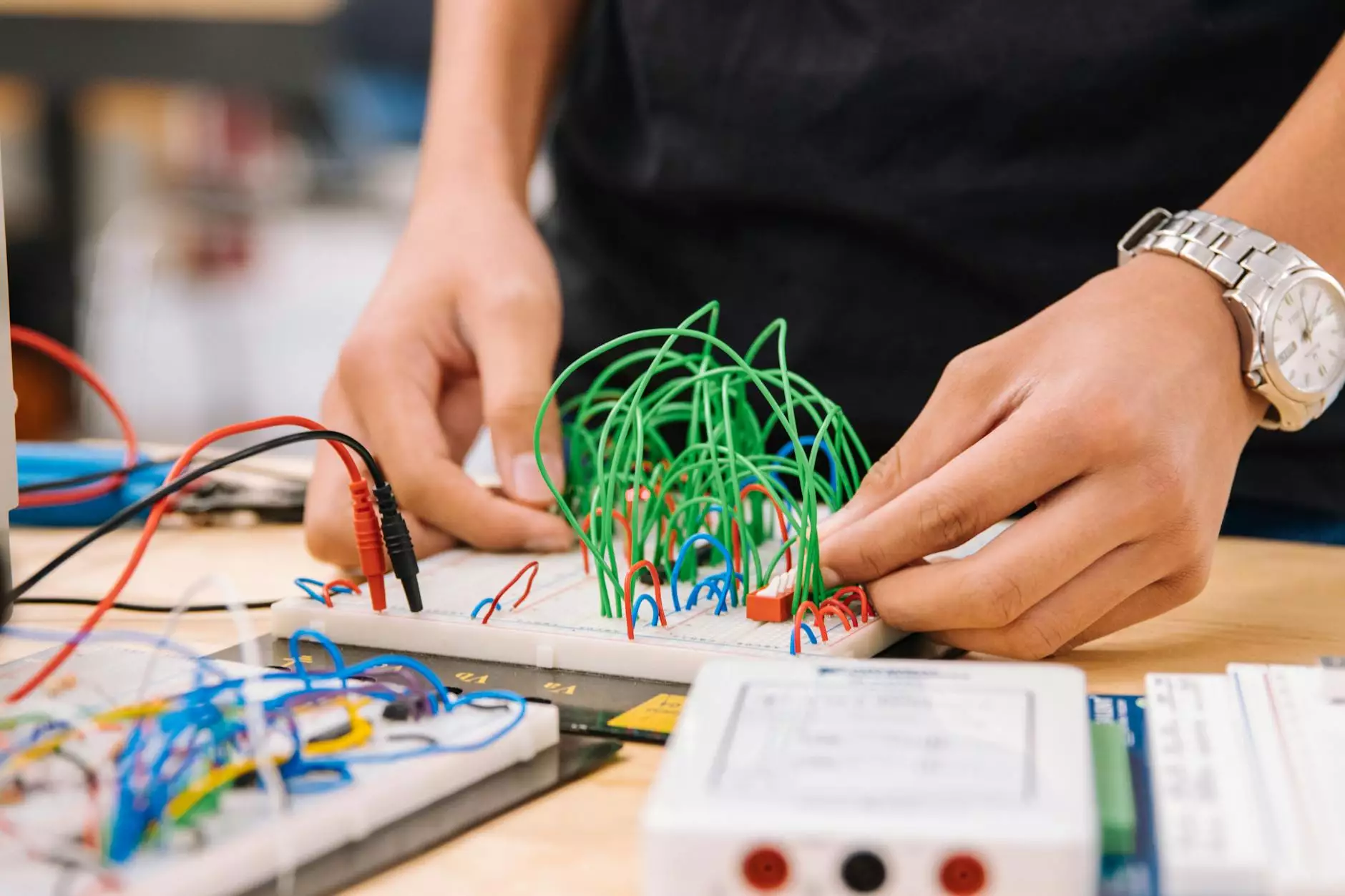

The Concept of Rapid Prototyping

Rapid prototyping refers to the quick fabrication of a physical part, model, or assembly using 3D CAD (Computer Aided Design) software. Typically employed in product design and development, this process allows businesses to translate their ideas into tangible forms, facilitating testing, evaluation, and iterative refinement.

Historical Overview

The origins of rapid prototyping trace back to the 1980s with the advent of 3D printing technologies. Initially, these processes were costly and limited to a few industries. However, advancements in technology and decreased costs have broadened accessibility, encouraging widespread adoption across various sectors.

Benefits of Rapid Prototyping and Manufacturing

Utilizing rapid prototyping and manufacturing offers a multitude of benefits that contribute to operational efficiency and market competitiveness. Below are some of the significant advantages:

- Speed: Rapid prototyping drastically reduces the time required to develop a product from concept to reality. This rapid turnaround allows businesses to respond swiftly to market demands.

- Cost-effectiveness: By identifying and rectifying design flaws early in the development process, companies can significantly decrease costs associated with extensive redesigns later in production.

- Enhanced Flexibility: With rapid prototyping, changes can be made almost on-the-fly, allowing for a more adaptable design process that can better address customer needs.

- Improved Communication: Prototypes serve as excellent communication tools between designers, engineers, stakeholders, and clients, conveying ideas in a more tangible manner.

- Innovation Facilitation: The iterative process inherent in rapid prototyping encourages experimentation and fosters a culture of innovation.

Applications of Rapid Prototyping and Manufacturing

Rapid prototyping and manufacturing are gaining traction across multiple industries. Here are some notable applications:

1. Metal Fabrication

In metal fabrication, rapid prototyping plays a crucial role in developing intricate designs and components. It allows fabricators to experiment with various materials and techniques, enabling the creation of precise, high-quality products.

2. Aerospace Industry

The aerospace sector benefits immensely from rapid prototyping due to its rigorous safety and performance standards. Prototypes can undergo extensive testing before full-scale production, ensuring reliability and compliance with industry regulations.

3. Automotive Industry

Automakers often utilize rapid prototyping to design and test new vehicle components. By analyzing prototypes, manufacturers can refine designs for efficiency and performance, ultimately leading to enhanced vehicle safety and consumer satisfaction.

4. Consumer Electronics

The fast-paced nature of the consumer electronics market means that companies must frequently innovate and release new products. Rapid prototyping allows for quicker design iterations, reducing time to market and aligning with consumer trends.

The Role of Technology in Rapid Prototyping and Manufacturing

The advancement of technologies such as 3D printing, CNC machining, and computer-aided manufacturing has significantly enhanced the rapid prototyping and manufacturing processes.

1. 3D Printing

3D printing, or additive manufacturing, is perhaps the most recognized method of rapid prototyping. It allows for the creation of complex geometries that are difficult to achieve with traditional manufacturing techniques. Materials can include plastics, metals, and even biological materials, expanding the possibilities for innovation.

2. CNC Machining

CNC (Computer Numerical Control) machining complements rapid prototyping by providing high precision and repeatability. It is particularly useful for creating metal prototypes that require high-strength materials and stringent tolerances.

3. Simulation Software

Advanced simulation software means that prototypes can be tested virtually before creation. This capability ensures that designs are optimized for performance and manufacturability, reducing the risk of costly errors during the prototyping phase.

Challenges in Rapid Prototyping and Manufacturing

While the benefits of rapid prototyping and manufacturing are substantial, some challenges persist:

- Material Limitations: Although 3D printing technology is rapidly evolving, there are still limitations regarding the variety and properties of materials available for prototyping.

- Regulatory Compliance: Industries such as aerospace and medical devices must navigate complex regulatory frameworks that can slow down the prototyping process.

- Initial Costs: Despite long-term cost savings, the initial investment in rapid prototyping technology can be significant, particularly for small businesses.

The Future of Rapid Prototyping and Manufacturing

Looking ahead, the landscape of rapid prototyping and manufacturing is poised for exciting developments. Key trends include:

1. Increased Automation

Automation in manufacturing processes is expected to rise, resulting in faster production times and reduced labor costs. Integration with machine learning and AI will facilitate more efficient designs and smarter manufacturing techniques.

2. Advancements in Materials Science

The ongoing research into new materials will enhance the capabilities of prototyping technologies. Materials with enhanced properties such as flexibility, strength, and thermal resistance will open new avenues for innovation.

3. Sustainability Efforts

As businesses become increasingly aware of their environmental impact, sustainable practices in rapid prototyping are on the rise. Techniques that reduce waste and utilize eco-friendly materials are gaining traction, aligning business success with environmental responsibility.

Conclusion: The Transformational Power of Rapid Prototyping and Manufacturing

In conclusion, rapid prototyping and manufacturing are not just trends; they are essential strategies that drive the future of business innovation and operational excellence. By embracing these advancements, companies, particularly in the metal fabrication sector like deepmould.net, can significantly enhance their competitive edge, streamline operations, and foster an environment of continuous improvement. As technology evolves, so too will the possibilities for businesses to innovate, creating products that meet and exceed consumer expectations. This transformational power firmly positions rapid prototyping and manufacturing as a cornerstone of modern enterprise development.