The Comprehensive Guide to Refrigeration Equipment

In the modern world, refrigeration equipment plays a crucial role in various industries, from food storage to pharmaceuticals. Understanding the nuances of this essential technology can immensely benefit businesses and consumers alike. In this detailed guide, we will explore the various aspects of refrigeration equipment, including its types, applications, maintenance, and potential advancements in technology.

What is Refrigeration Equipment?

Refrigeration equipment consists of machines and components used to remove heat and maintain low temperatures in various environments. These devices are critical in preserving food freshness, ensuring pharmaceutical integrity, and facilitating industrial processes that require temperature control. The effectiveness of refrigeration equipment is vital for the supply chain, particularly in sectors like food service and healthcare.

Types of Refrigeration Equipment

Understanding the different types of refrigeration equipment available in the market is essential for any business looking to leverage these systems for improved operational efficiency. Here are the primary categories:

1. Commercial Refrigeration Equipment

This category includes a variety of refrigeration devices used in retail environments, such as:

- Display Refrigerators: These are often found in grocery stores and supermarkets. They display products while keeping them at safe temperatures.

- Walk-in Coolers and Freezers: Essential for large-scale food storage, allowing easy access to various perishable items.

- Refrigerated Transport Vehicles: Trucks and vans equipped with refrigeration units for transporting goods at controlled temperatures.

2. Industrial Refrigeration Equipment

Large-scale operations rely on industrial refrigeration systems to maintain product integrity and optimize the production process. Key types include:

- Chillers: Used in manufacturing processes for maintaining required temperatures.

- Ammonia Refrigeration Systems: Common in facilities requiring significant cooling power, such as meat processing plants.

- Refrigeration Compressors: The heart of any refrigeration system, responsible for compressing and circulating refrigerants.

3. Domestic Refrigeration Equipment

Household refrigeration includes smaller units used in everyday life, such as:

- Refrigerators: Essential appliances in homes for food storage and preservation.

- Freezers: Standalone units for long-term food storage.

- Wine Coolers: Specially designed for the optimal storage of wine at controlled temperatures.

Applications of Refrigeration Equipment

Refrigeration equipment serves a variety of applications across multiple industries. Here's a closer look:

1. Food and Beverage Industry

In this sector, refrigeration is vital for preserving food quality and safety. From farm to table, refrigeration:

- Maintains the freshness of produce.

- Extends the shelf life of meat and dairy products.

- Provides optimal conditions for drinks, ensuring quality and flavor.

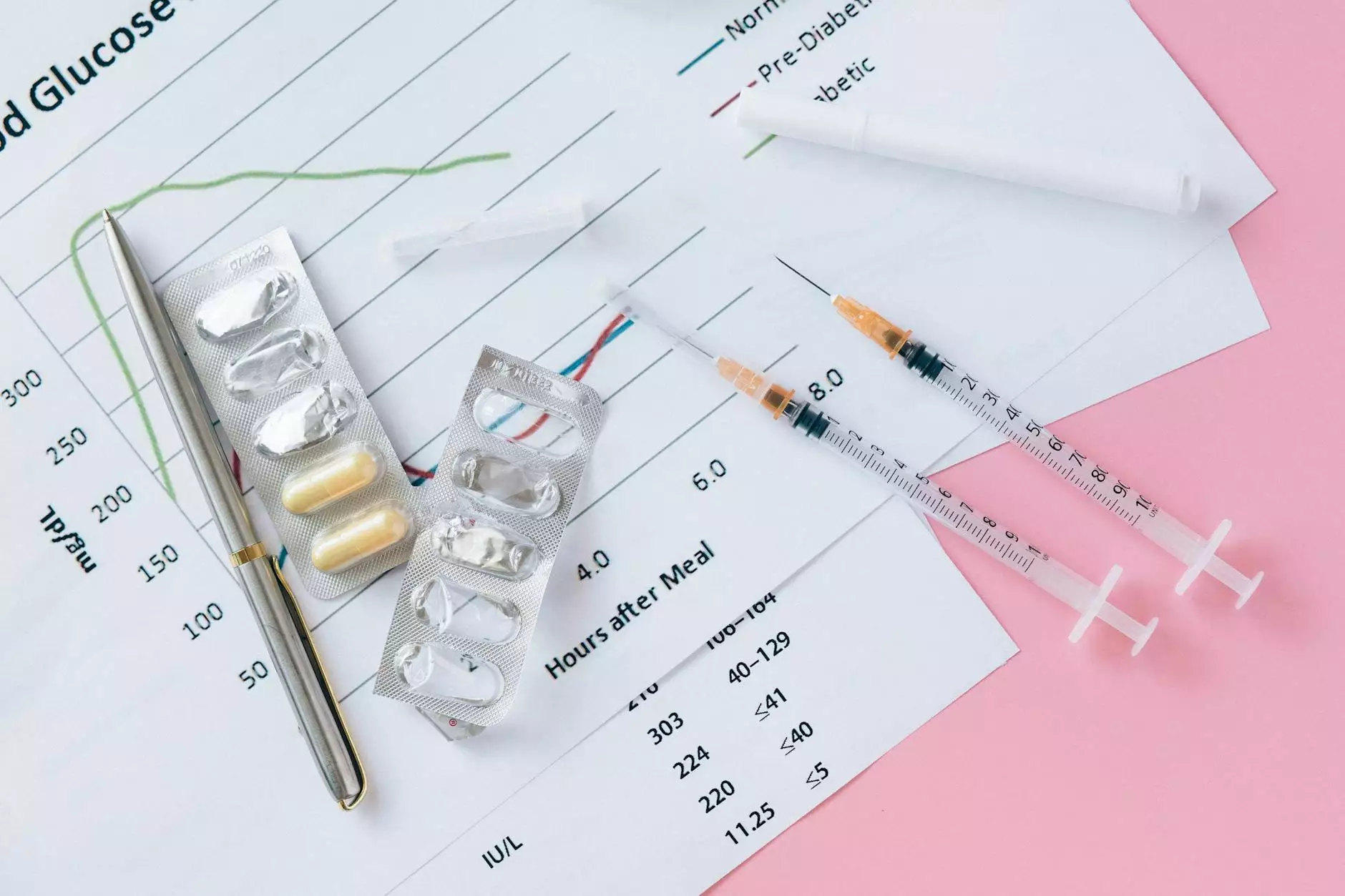

2. Pharmaceutical and Healthcare Industry

In healthcare, maintaining the efficacy of medications and vaccines relies on stringent temperature control. Key points include:

- Refrigerators are used for storing sensitive medications that require cold storage.

- Vaccines must be kept at specific temperatures to remain effective.

- Blood banks utilize advanced refrigeration systems to preserve blood supplies.

3. Industrial Manufacturing

Many manufacturing processes require reliable refrigeration systems for quality assurance. Examples include:

- Cooling during chemical production to prevent overheating.

- Temperature regulation for certain assembly processes.

- Preserving raw materials at optimal temperatures.

Benefits of Using Quality Refrigeration Equipment

Investing in high-quality refrigeration equipment yields numerous benefits, including:

- Improved Efficiency: Well-designed refrigeration systems consume less energy and provide more effective cooling.

- Enhanced Product Safety: Eliminates the risk of spoilage and waste in perishable goods.

- Cost Savings: Efficient units reduce electricity costs over time and minimize maintenance expenses.

- Better Compliance: Adhering to health and safety regulations is easier with reliable refrigeration equipment.

Maintenance Tips for Refrigeration Equipment

Proper maintenance of refrigeration equipment is crucial for ensuring longevity and effective performance. Here are several tips:

1. Regular Cleaning

Keeping units clean is essential. Dust and debris can impede airflow and decrease efficiency. Schedule regular cleaning of coils and filters.

2. Monitor Temperature Settings

Ensure that the temperature settings are accurate and appropriate for the items being stored. Use calibrated thermometers for regular checks.

3. Inspect Door Seals

Examine the door seals routinely to prevent cold air from escaping. Damaged seals should be replaced immediately to maintain efficiency.

4. Professional Servicing

Consider professional servicing at least once a year to catch any potential issues before they escalate.

Future Trends in Refrigeration Equipment

The world of refrigeration equipment is constantly evolving. With technological advancements in sustainability and energy efficiency, here are some trends to watch:

1. Eco-Friendly Refrigerants

The industry is gradually moving away from harmful refrigerants (e.g., HFCs) to more environmentally friendly options (e.g., hydrocarbons and natural refrigerants).

2. Smart Refrigeration Systems

Incorporation of IoT (Internet of Things) technology allows for real-time monitoring and management of refrigeration systems, enhancing efficiency and operational oversight.

3. Increased Energy Efficiency

Advances in design and technology are leading to more energy-efficient systems that save money on operating costs while reducing environmental footprints.

Conclusion

In conclusion, refrigeration equipment is an indispensable component of modern business operations across various sectors. By understanding its types, applications, benefits, and maintenance requirements, businesses can make informed decisions that enhance operational efficacy. Moreover, keeping an eye on future trends will allow industries to adapt and innovate, ensuring they remain competitive in an ever-evolving landscape. Embracing the potential of refrigeration technology is not just a necessity but a strategic advantage for businesses looking to thrive in today's market.